The region of South Dead Sea is today a singular mix of verdant fields, small villages, white sediments hills, rocky backgrounds and, looking to the North, the last water bodies of a dying lake. At the first look, nothing indicated that this plain hosted in the past a prosperous and quite large city, in the surroundings of the modern Ghor Es-Safi village. Zoara is many time mentioned in the Ancient Testament under the name of Zoar or Segor (and also Bela) and is generally known as the place where Lot sought refuge after the destruction of Sodom and Ghomorrah. (For biblical references, click here)

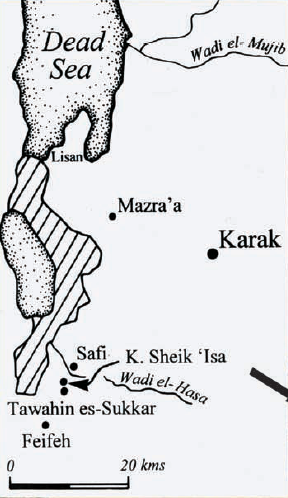

R. Jones art., ref. below | Benefiting of an ideal location not far from the Southern edge Dead Sea, where a port was probably situated, Zoara was over the historical periods a trade crossroad as well as a wealthy rural area enjoying ideal farming conditions, ideally located on the bank of the large Wadi Hasa as well as on the trade route linking the Transjordanian plateau with South Palestine cities. The city is mentioned on the Madaba map under the name of Zoora, associated with palm trees. During the Byzantine period, Zoara was the seat of a bishop that attended the Nicaea Council. The considerably large Christian population living in Zoara at that time is attested by numerous tombstones. |  R. Jones art., ref. below |

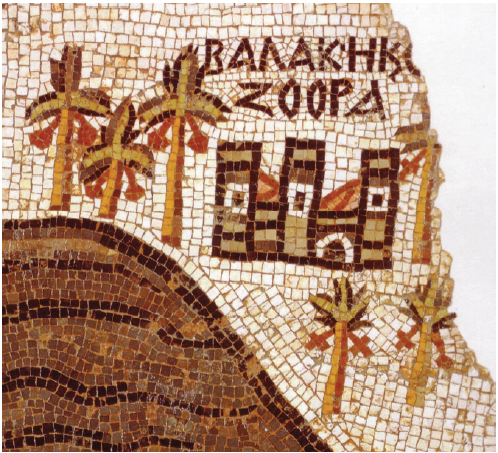

Detail of the Madaba Map mosaic mentioning the city of "Zoora" | Byzantine period tombstone discovered in Ghor Safi |

ph. Michele Piccirillo, ACOR Newsletter vol. 22.2 |  ph. Trevor Springett, ACOR Newsletter vol. 22.2 |

At the early Islamic period, Zoara is a busy market town, especially known for the production of dates and indigo. However, the city is going to witness a extraordinary prosperity under the impulse of the "Islamic Agricultural Revolution" with the introduction of the sugar cane and the development of a sugar industry. The sugar cane was imported from the East further to the Islamic conquest. From the 9th century, and especially during the Ayyubid and Mameluke periods till the 14th century, the sugar production in the Jordan Valley is booming and Zoara becomes a major center for the sugar agro-industry.

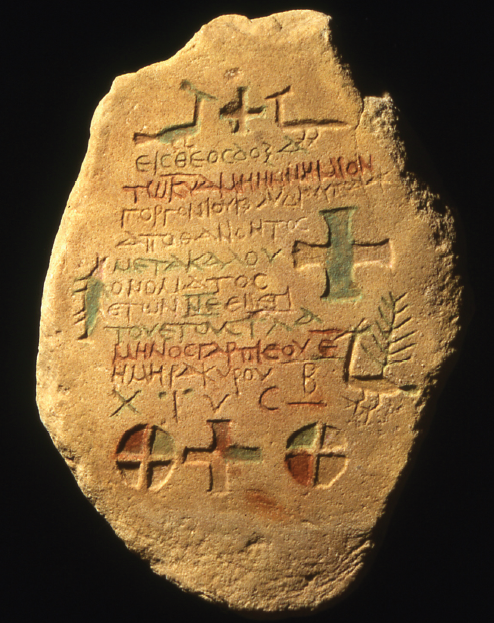

Map showing locations of sites having connection with sugar | |

R. Jones art., ref. below | Archaeological finds show that the sugarcane was cultivated and refined all along the both banks of the Jordan Valley. Not less than 43 sugar factories have been identified in the Jordan Valley, with a majority (34) on the eastern side of the valley along the bottoms of the lateral wadies that provided the water powering to the mills, with a notably example near Pella. The South Ghor region counts three factories, in Mazra'a, in Fifa and in Safi. Nevertheless, the recently excavated Safi (Zoara) sugar factory (Ar. masnat Es-Sukkar) is the best example and the largest installation of the whole region, which includes two well preserved presses and a boiling house where many typical sugar conical potteries have be discovered. The pottery dating indicates a start up at the 8th century, but the peak production is situated between the 11th and the 14th centuries. S |

The Zoara plain gathered the ideal conditions for sugar cane cultivation: a tropical climate, profusion of water flowing from the Wadi Hasa and a richly mineralized sedimentary soil. As the sugar cane imposes hard working conditions in heat and humidity, the labor force was reinforced by workers from abroad. We also know that zebus were imported and used as draught animals. |  |

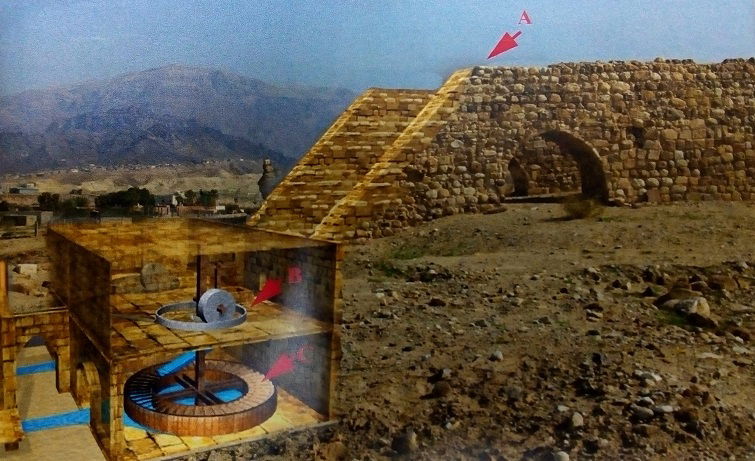

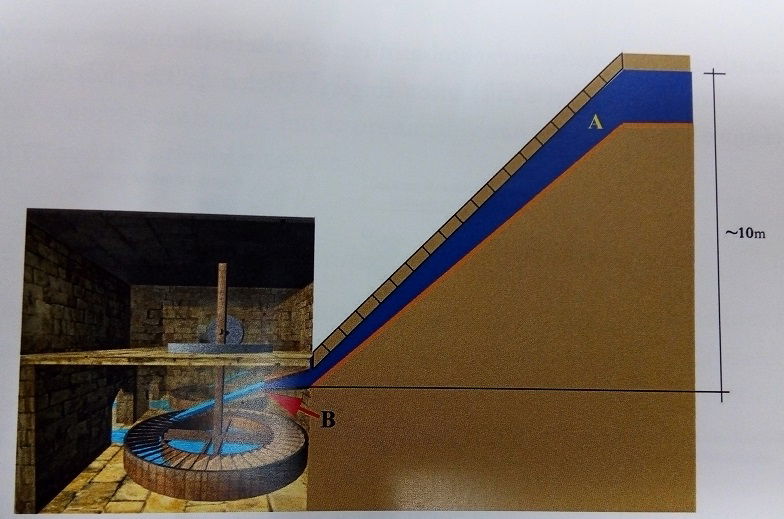

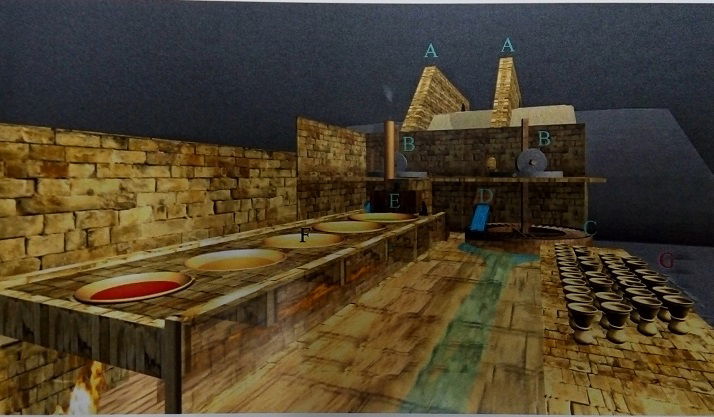

Safi sugar factory comprised two side by side pressing units, each one consisting in a lower vaulted room containing the water-powered mechanism and an upper floor press to which the rotation dynamic was transmitted through a hole to the press (Fig 1 and 2) . A large aqueduct (1.5 m wide and 2m deep) conducted the water drawn from the adjacent Wadi Hasa till over the factory, where the flow was partly diverted at right angles to two oblique channels mounted on large walls and leading to the units, while the remaining water continued straight towards an adjacent flour-mill. Arrived to the edge of the diverted channels, the water whizzed down along a covered ramp (10 m in vertical drop) till the mechanism in the lower rooms for activating the rotation of horizontal paddled wheels, each one 4.70 m in diameter, as traces carved in the ground demonstrate (Fig 3 and 4) . Each wheel rotated an axis forwarding the force to the upper room and powering the related sugar press, consisting in a vertical round stone rolling in a circular pressing bed 3.10 m in diameter. The volume, speed and gravity of the water flow arriving on the paddled wheels were precisely calculated to produce the suitable impulse in the wheels in order to give the right force to the heavy press stone situated above, a process which demonstrates an excellent mastery in the physic of the forces transmission (Fig. 5 and 6). The juiced extracted from the sugarcane was collected and transported through a channel over a little arched bridge till the boiling house (Fig. 7 and 8) , while the water coming out off the wheels was diverted for irrigating the surrounding fields.

Fig. 1: reconstitution | Fig. 2: front view with the water channels and the two upper presses |

drawing S.Witkin, "The Origin Of Sugar Industry..." ref. below |  |

Fig. 3: reconstitution of the hydraulic channels | Fig. 4: front view of one of the channels |

drawing Y.Dray, "The Origins of the Sugar Industry..." ref. below |  |

Fig. 5: press with vertical wheel | Fig. 6: Mechanism rotation marks on the ground of one of the lower chamber |

|  ph.D.Comar, "The Origins of the Sugar Industry..." ref. below |

Fig. 7: reconstitution of the evacuation channel via an arched bridge | Fig. 8: over view of one of the presses with evacuation channel |

photo K. D. Politis, graphics Y. Dray, "The Origins of the Sugar Industry..." ref. below |  photo D. Comar, "The Origins of the Sugar Industry..." ref. below |

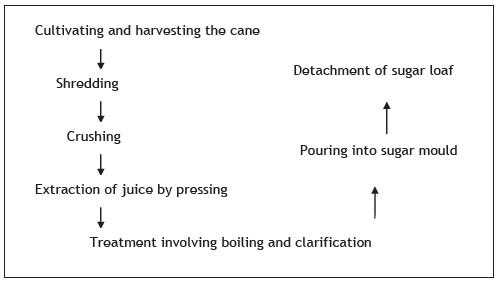

After harvesting, the sugar production consist in at least 6 steps:

Richard Jones art., ref. below

Richard Jones art., ref. below

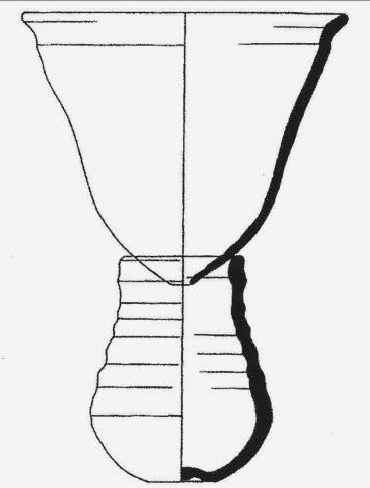

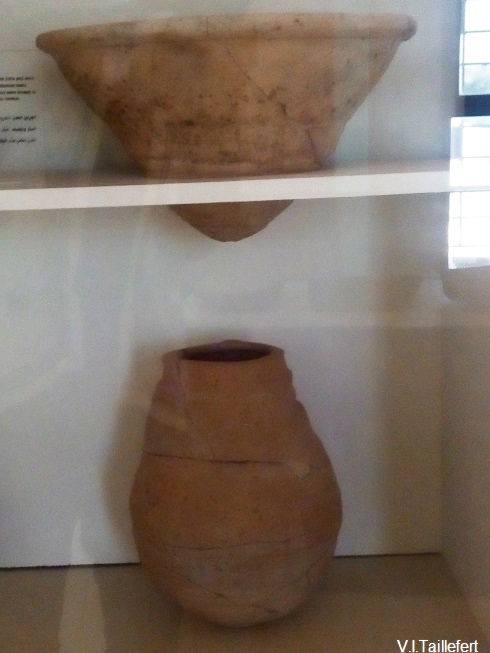

The boiling house contained a range of furnaces over which the sugar juice was boiled in large cauldrons at low heat (Fig. 9 and 10). It was then poured in conical recipients drilled in the bottom in order to let drain the heavy molasses in a jar placed under the cone and recuperate the crystallized sugar loaf from the cone, once it was completely dry (Fig. 11 and 12) . Extracting the sugar loaf out of its cone may eventually requested to break the cone, as suggested by the uncountable cones sheds found on the spot (Fig. 13) . A second, or eventually a third boiling of the molasses, would provide a more refined kind of sugar. However, we ignore which refining level process was reached in the Safi sugar factory.

Fig. 9: reconstitution | Fig. 10: cauldron exhibited at the Museum of The Lowest Point on Earth |

|  |

Fig. 11: conical recipient and jar | Fig. 12: conical recipient and jar exhibited at the Museum of the Lowest Point on Earth |

lithography W Clark, "The Origins of the Sugar Industry..." ref. below |  |

Fig. 12: pottery shards pictured on site | |

| |

The sugar industry in the Jordan Valley was so important during the Mameluke period (12th - 14th centuries) that the sultan appointed a special supervisor in the region for managing the production, collection and finances. Plantation and factories were declared royal property. For the state, the sugar industry represented an excellent value and a highly profitable trade. As sugar can be stored over a long period, it allows speculation by stockpiling during the high productive years for releasing the stocks at advantageous price during the poor yield years. At long term, sugar was a relative stable value, bringing constant taxes revenues to the Caliphate. From Zoara, the sugar was transported mainly to Gaza and from there exported to Europe.

Engraving Jan Collaert ca. 1600 (Netherland) showing the sugar processing | In the 15th century, the sugar production fall in disuse in our area. From Near and Middle East, the technology was brought to Cyprus and Rhodes, and from there followed the Mediterranean Europe coast till the Portugal, then Madeira, the Canaries, Santiago and Sao Tome...The development of the Mediterranean sugar production was at its turn supplanted by the transfer of the sugarcane to Central America, where it found perfect tropical conditions. However, even if the migration of the sugar industry towards the West strongly impacted the Middle-East production by breaking down its market, other factors also have probably played a role: the decrease of the rainfalls after 1400 AD, plagues and civil wars. Along idea climatic conditions, the sugar industry is demanding in labor force for its cultivation, production, refinement and transportation. It requests a stable political and social environment as well as a strong financial support. While those conditions where perfectly gathered during the 12th - 14th centuries, the degradation of the political situation in the next period turned into troubles and depopulation that the sugar industry could not afford. |

|

The site of Safi sugar factory remains an amazing testimony of the past flourishing sugar agro-industry and the impressive mastery in the knowledge in fluids dynamic, physics and chemistry at that period. The name of Zoara became Zughar and is likely the origin of the modern name Ar. Sukkar, Eng. sugar, All. Zucker, Fr. sucre.

References:

The Origins of the Sugar Industry and the Transmission of Ancient Greek and Medieval Arab Science and Technology from the Near East to Europe. Proceedings of the International Conference Athens 23 May 2015. Edited by Konstantinos D. Politis

Konstantinos D. Politis: www.researchgate.net/publication/331843694_The_Sweet_Industry_-_Cane_Sugar_Production_Technology_in_Antiquity/download

Konstantinos D. Politis: conference at ACOR: www.acorjordan.org/2016/03/02/sugar-safi-and-schep/

Bethany J. Walker: https://journals.openedition.org/beo/160?file=1

www.acorjordan.org/wp-content/uploads/2018/09/22.2_final.pdf

www.pef.org.uk/oldsite/Pages/Projects/Zoara.htm

www.hsnes.org/current_project_020.htm

https://digitalarch.org/blog/2017/3/29/small-places-and-big-histories-the-lowest-place-on-earth

www.mota.gov.jo/NewsView.aspx?NewsId=1247

Graham Chandler, George Azar: https://archive.aramcoworld.com/issue/201204/sugar.please.htm